History

Nhat Nam Mechanical Co.,LTD was established in 2016, specializing in cutting, bending, stamping, Welding, powder coating for sheet metal.

- 2004- 2015: Study and work in Japan ( 東洋プレス工業、TOYOTA BODY , Honda R&D)

- 2016-2018: established Nhat Nam Mechanical Co., Ltd (build factory, invest in basic sheet metal processing equipment)

- 2019: Invest in powder coating equipment, invest in CNC laser sheet cutting machines.

- 2020: Invest in robot welding machine, get ISO 9001: 2015 quality management certificate

- 2021: Invest in CNC punching machine (AMADA Japan), build 2 factory with a scale of 4000𝑚^2 with automatic powder coating system with the goal of producing high quality products for export to USA, JAPAN markets.

| Company Name | NHAT NAM MECHANICAL CO.,LTD |

|---|---|

| Office Location |

36 Garland - Phuoc Dien, 72 Duong Dinh Hoi street, Phuoc Long ward, Ho Chi Minh City, Viet Nam. TEL: +84-(0)28 6282 8133 |

| Factory Location |

Tan Cang Hamlet, Phuoc Tan Ward, Dong Nai TEL : +84-(0)25 1286 0700 |

| General Director | TRAN QUY |

| Foundation | March 2016 |

| Capital | 1.000.000 USD |

Message from the General Director

After learning the techniques of sheet metal processing in Vietnam, I had the opportunity to come to Japan to work and study for 12 years. Here I tried to work and study every day. Get access to advanced techniques at TOYOTA BODY, Honda Japan R&D center. Have the opportunity to learn the "monodukuri" philosophy of production, which is famous in Japan.

In 2015, I returned to Vietnam to realize my dream. In March 2016, I established Nhat Nam Mechanical Co., Ltd. specializing in processing and manufacturing metal products. With the production motto: "Japanese technique - Vietnamese hand" to make good quality products by Vietnamese hands. Started as a machining company but we aim to produce a highly technical finished product. Therefore, it is very important to train highly technical human resources and invest in modern equipment. Currently, we can produce a complete sheet metal product in the factory through the following stages: CNC laser cutting, bending, stamping, robot welding, electrostatic painting, assembly. The production process encapsulated in such a factory will reduce costs, improve product quality, and be proactive in the production schedule. This is the key to our management 3 Best

We continue to pursue the path of a manufacturing company< monodukuri kaisha > The goal is to become an integrated company from R&D and design to production, delivering convenient, high-quality, and user-safe products. All employees of Nhat Nam Mechanical always unite and strive to contribute more to society.

General Director Tran Quy

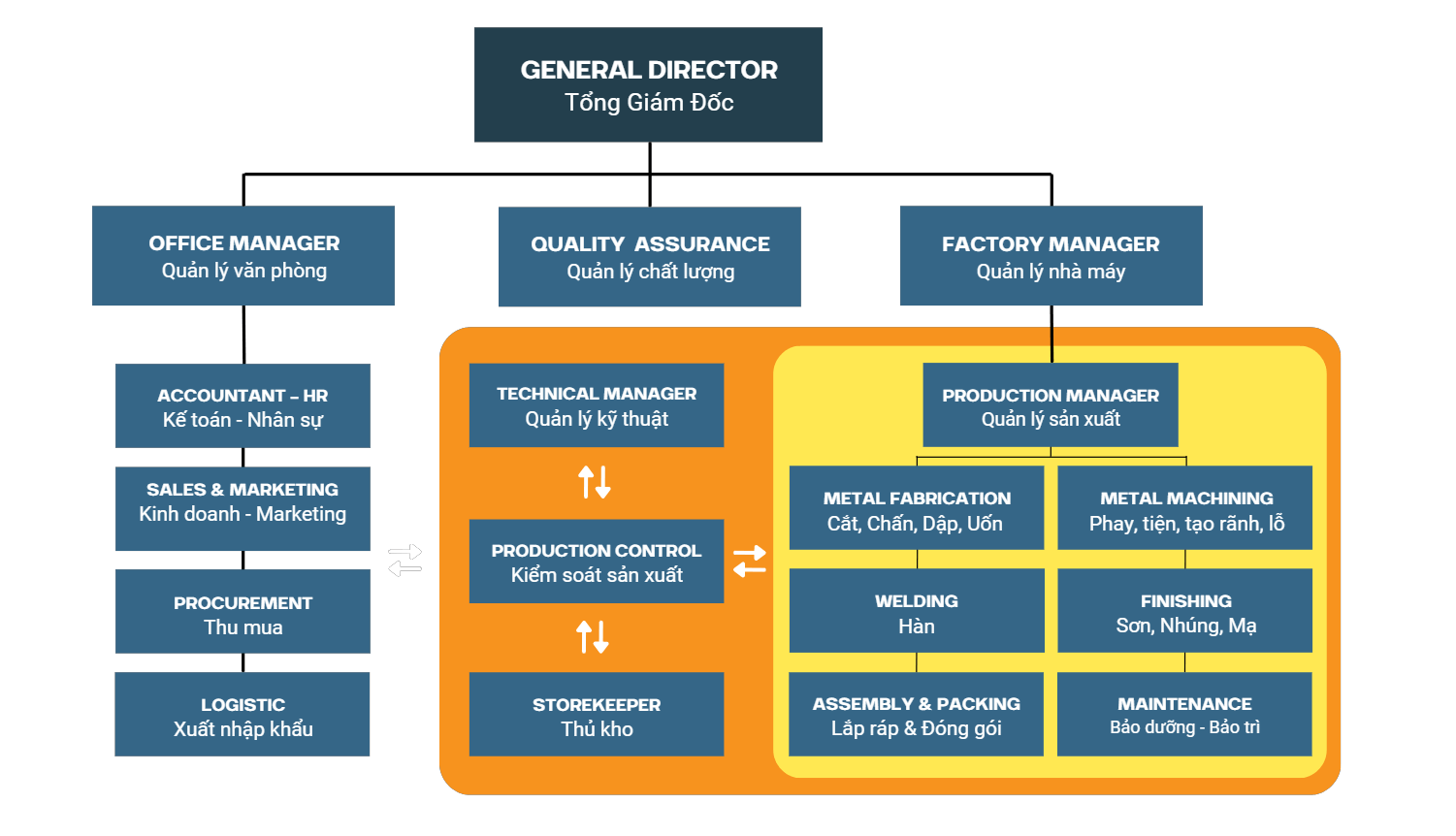

Organization chart

We operate and organize according to ISO 9001:2015

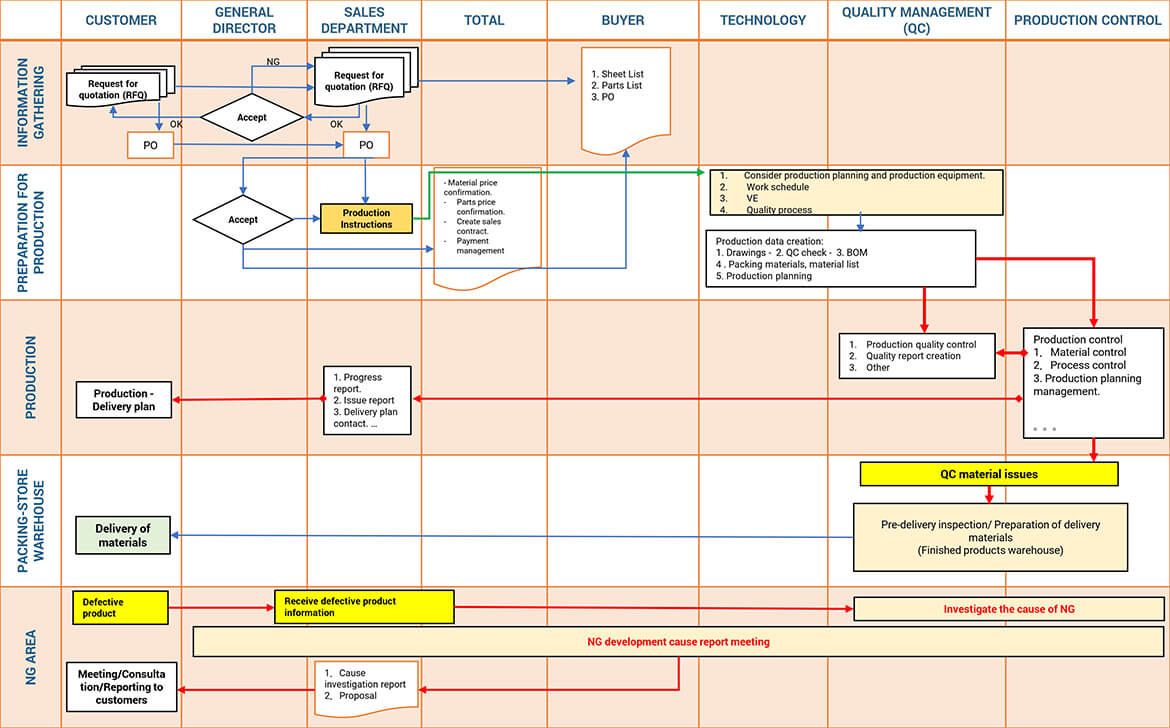

Business Workflow:

The investment in a factory with most of in-house services (all stages are deployed in the factory), and the application of ERP information technology helps us to manage 3 factors:

- Best quality.

- Most competitive price.

- The best delivery time.

Our Team

Nhat Nam Business Motto

Our motto is to bring customers and partners "Peace of mind - The absolute trust" when using our services and products.

- Customers: Peace of mind about quality - Peace of mind about progress - Peace of mind about price.

- Always changing to keep up with the development of the world and meet customer requirements.

Philosophy:

- A positive attitude helps us to live a full and happy life.

- A team: Keep learning - Practicing - Creating - Uniting is a sustainable development team.

- A sustainable development company will contribute more to society.

Vision:

- The leading export sheet metal processing company in Vietnam.

- Professional OEM factory

Main business lines

Processing service:

- Sheet metal processing: CNC laser cutting, CNC machine parts processing, sheet metal stamping processing.

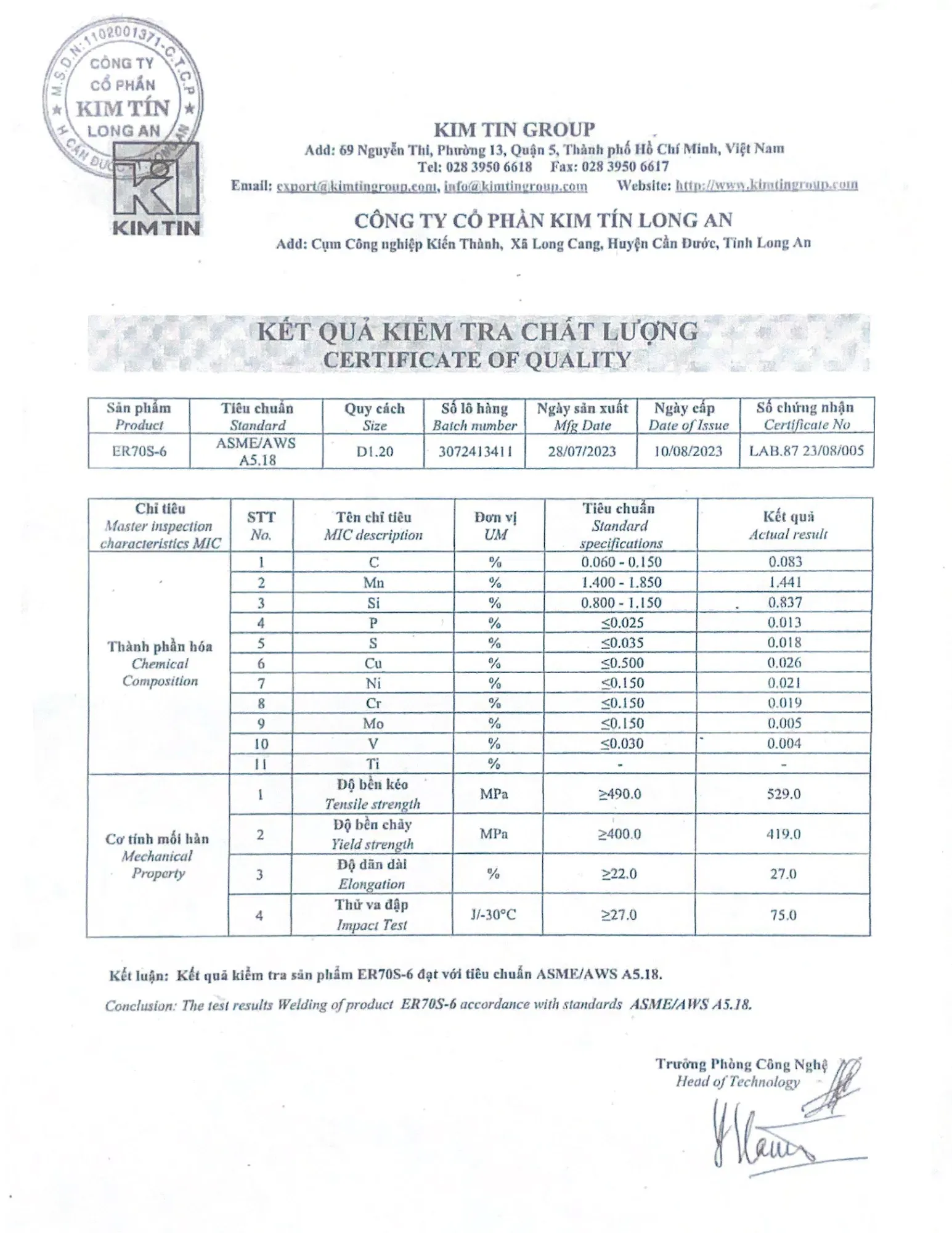

- Welding: Tig, Mig, robotic welding, spot.

- Processing powder coating, hot dip galvanized, chrome plating, metal polishing.

Production of products:

- Metal components: chassis, chassis, agricultural equipment, household appliances, construction.

- Furniture products: chair frames, tables of all kinds, iron beds, iron cabinets, kitchen shelves.

- Equipment used for the plant: loading steering wheel, conveyor, operating floor, storage tank, piping, ...

- Executing and installing warehouse shelves, product display shelves, iron pallets, trolleys.

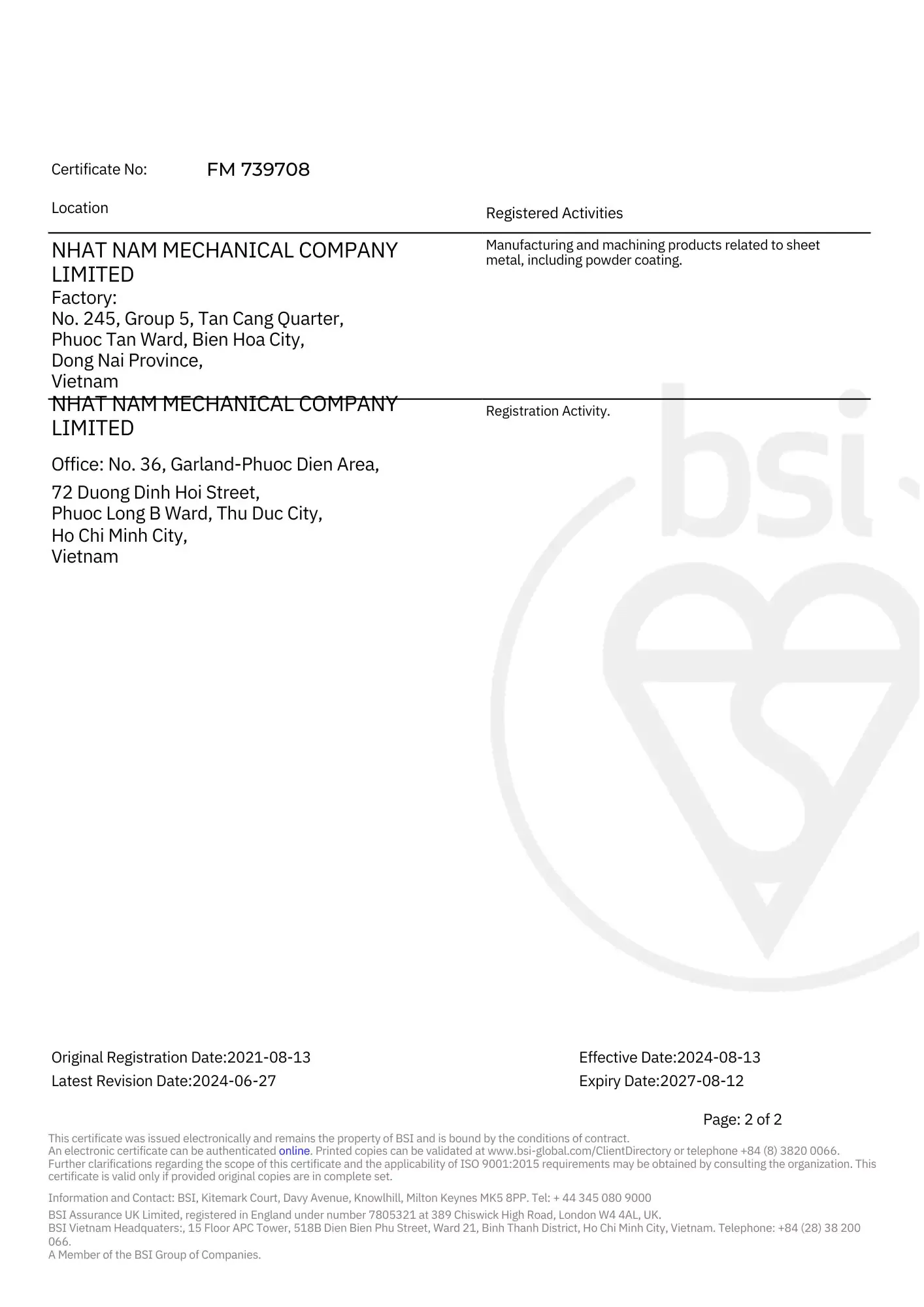

Certificate

ISO Certification:

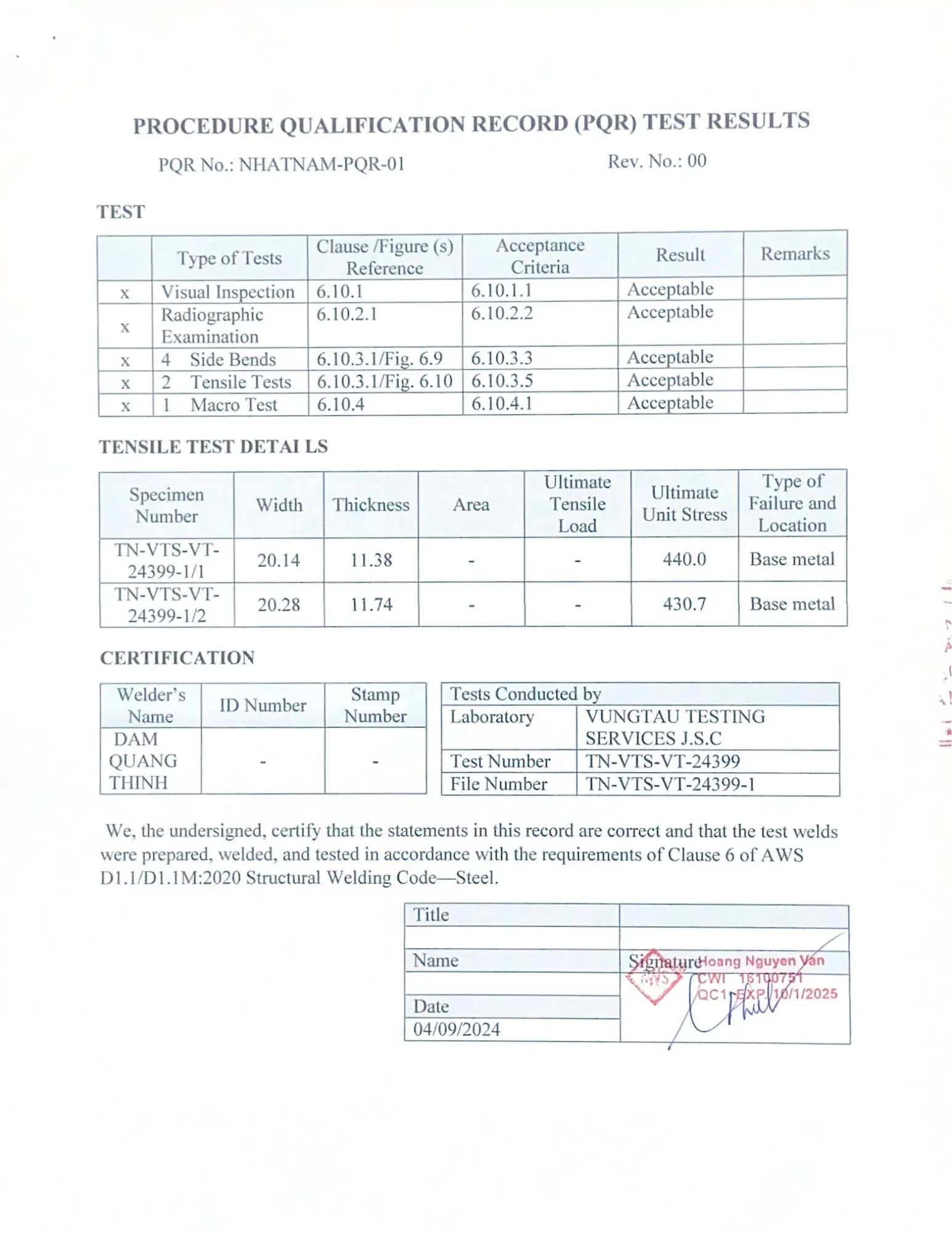

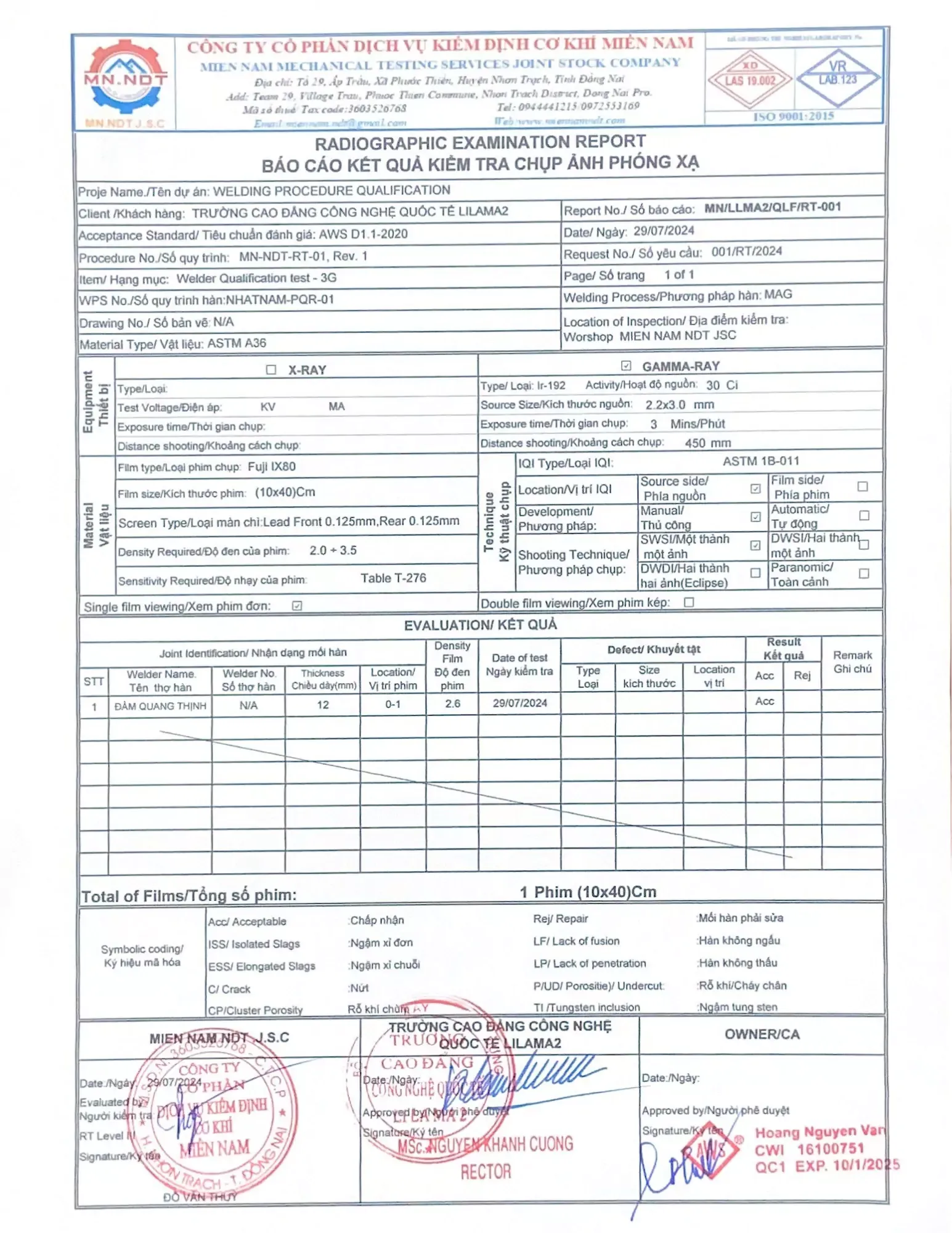

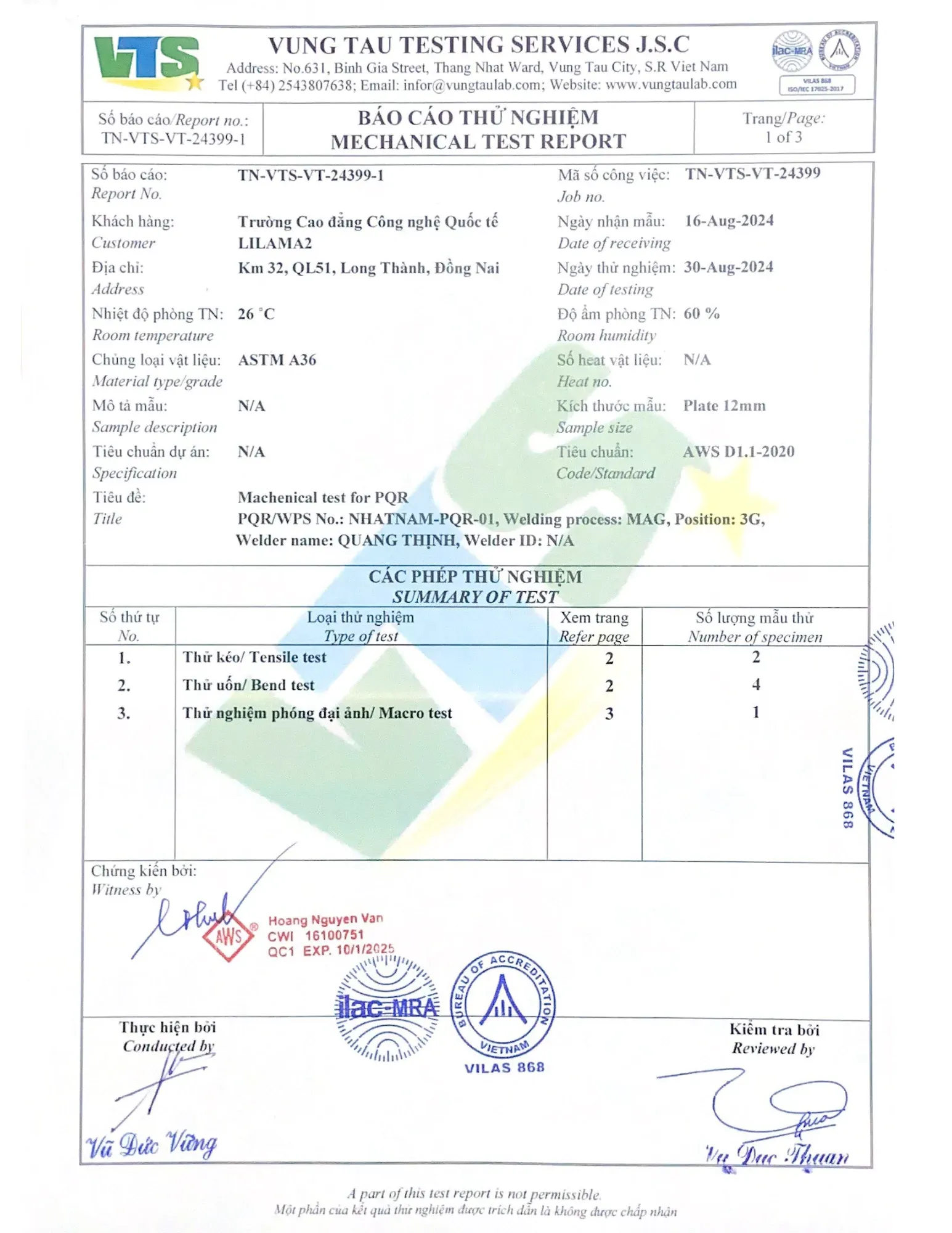

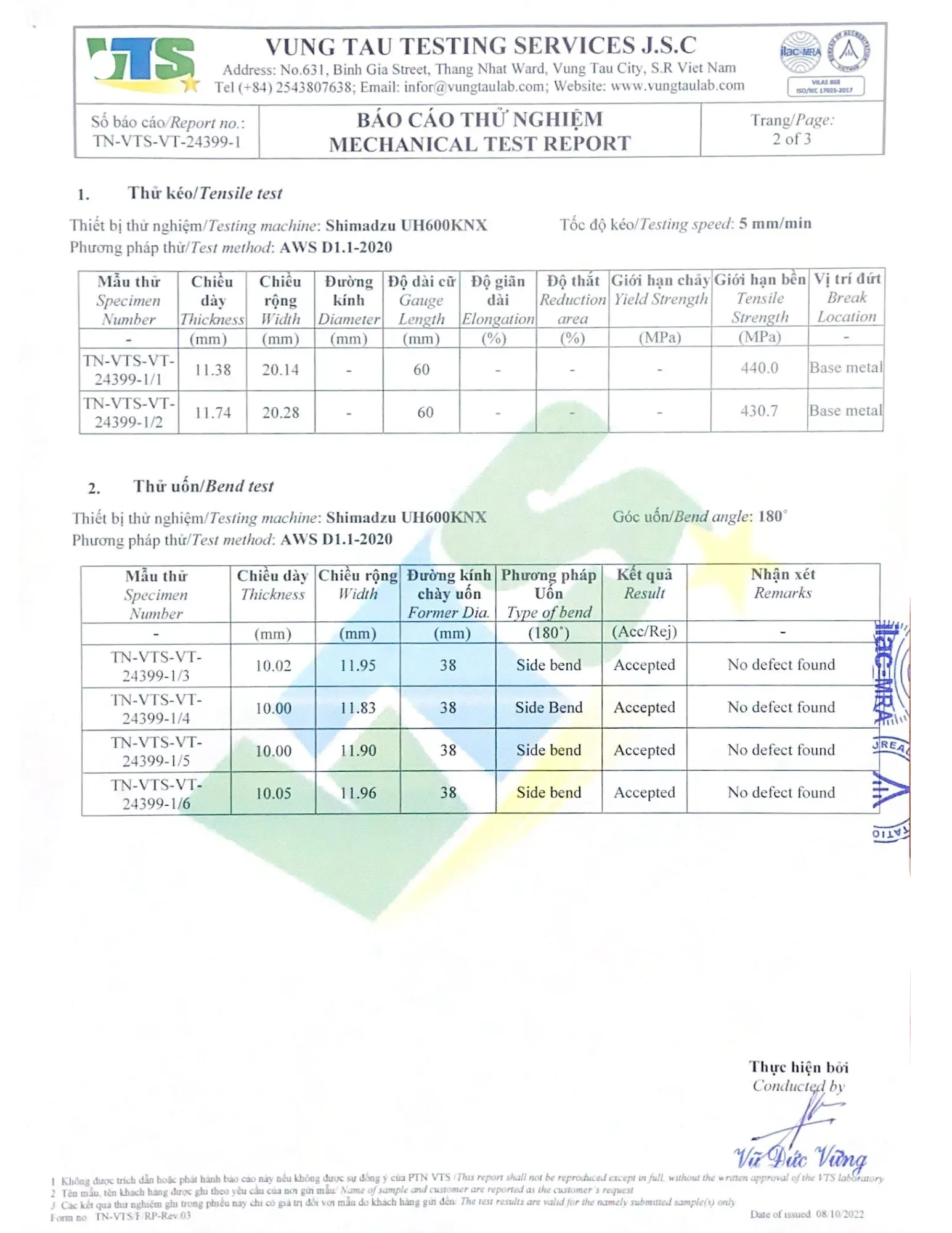

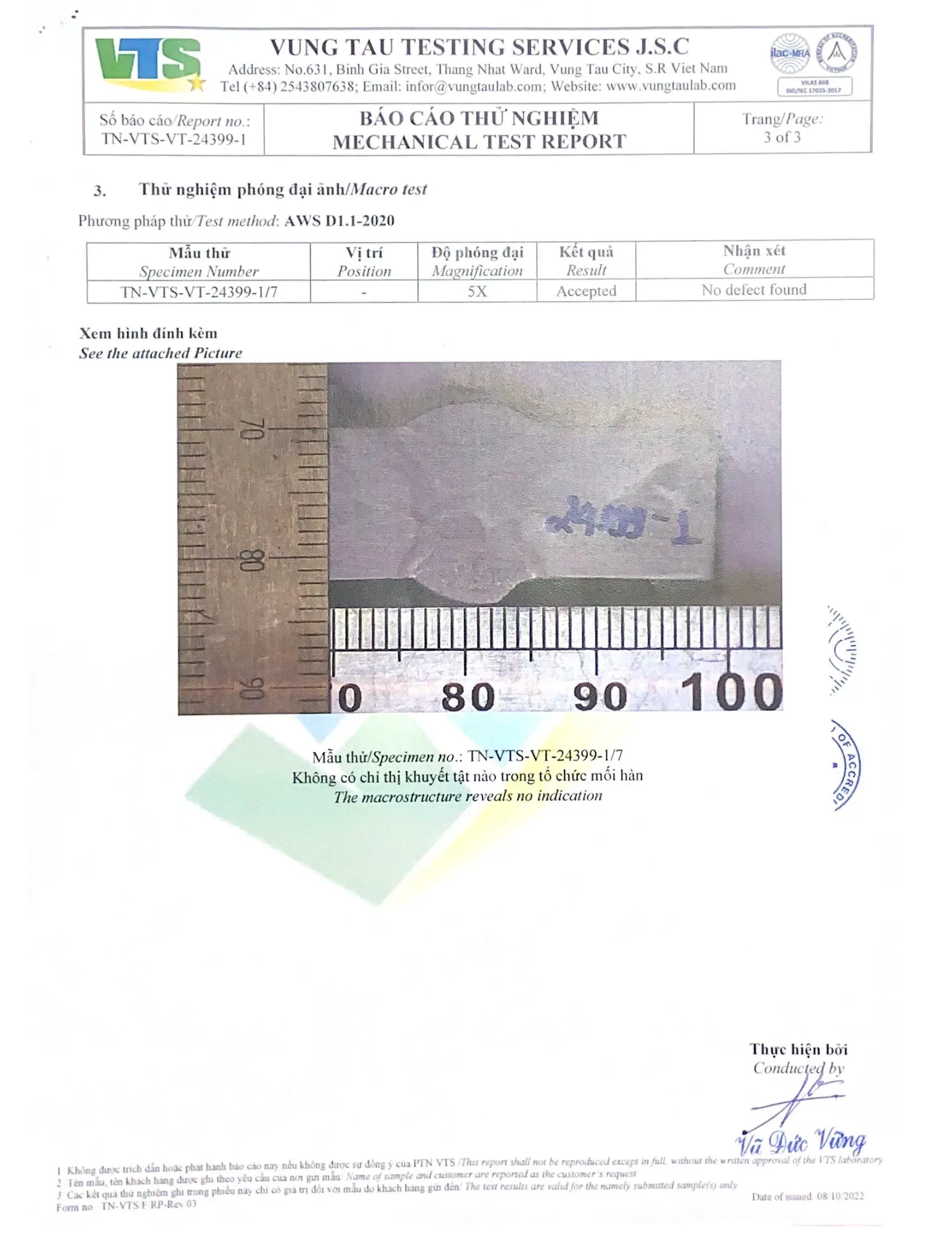

Welding Procedure Specification (WPS):